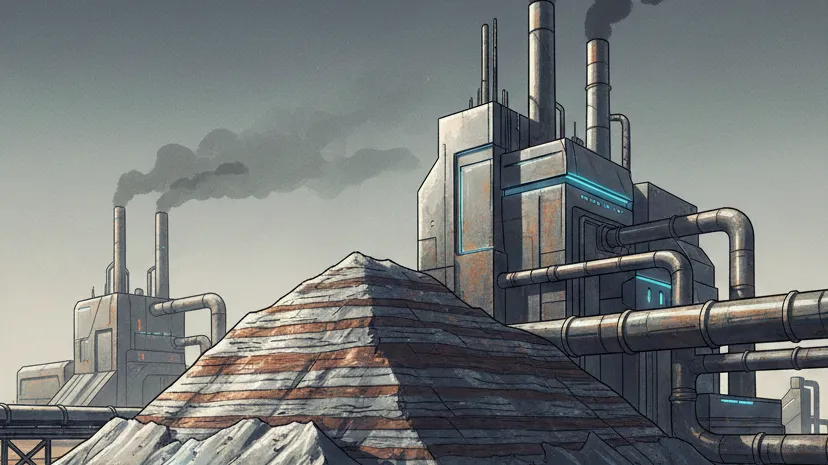

Langpan Commissions Second Chrome Processing Plant

Mantengu commissions Langpan’s second chrome plant, boosting capacity and unlocking value from tailings with no immediate mining cost.

Mantengu Mining has reached an important operational milestone with the successful commissioning of Langpan Mining’s second chrome processing plant, completed on 10 December. The new facility is expected to significantly lift production capacity while unlocking additional value from existing chrome tailings, all without the need for immediate mining expenditure. This development strengthens Mantengu’s strategy of generating near term cash flow through low cost processing assets.

The newly commissioned plant has a processing capacity of 50 tonnes per hour and will require approximately 31,500 tonnes of chrome ore feedstock to operate at planned levels. Langpan currently has an estimated 300,000 tonnes of chrome rich tailings available on site, providing around 10 months of feed at current throughput rates. These tailings are already carried as work in progress inventory, meaning they can be processed without incurring additional cash mining costs, a key advantage in managing operating margins.

With both chrome plants now in operation, Langpan’s combined facilities will require roughly 60,000 tonnes of feed per month. Extensive testwork on both the tailings material and the processing plant was completed by Gravitas Innovations, providing confidence in the recoveries and operational performance of the expanded processing setup. The commissioning of the second plant therefore marks a transition from single plant operations to a scaled processing platform.

In addition to chrome recovery, the tailings also contain platinum group metals, which have not yet been valued or recorded on Mantengu’s balance sheet. The company has indicated that further testwork will now be undertaken to assess the recovery potential and economic significance of these PGMs. If successfully quantified, this could represent an additional value stream beyond chrome, enhancing the overall economics of the Langpan operation.

From a broader industry perspective, Mantengu’s progress highlights the growing importance of tailings reprocessing within Africa’s mining sector. By extracting value from existing waste material, companies can reduce environmental liabilities while generating revenue at relatively low cost. For Mantengu, the successful commissioning of the second chrome plant not only boosts production capacity but also lays the groundwork for future investment decisions around platinum group metals, potentially strengthening its long term growth profile within the region’s diversified minerals landscape.

Mini-Glossary

- Commissioning: The process of testing and bringing a new plant or facility into operational service.

- Tailings: Residual material left after the extraction of valuable minerals from ore.

- Tonnes per hour: A measure of processing capacity indicating how much material a plant can treat in one hour.

- Work in progress inventory: Materials that have already incurred costs and are ready for further processing.

- Platinum group metals (PGMs): A group of precious metals including platinum, palladium, rhodium, and others, commonly used in catalytic and industrial applications.

Editor: Vural Burç ÇAKIR